OIL, GAS, & CHEMICALS

REFINERY BLENDING FOR GASOLINE, FUEL OIL, & DISTILLATES

Technics Blending Solutions can be extended to Refinery Systems where feedstocks are homogenized to produce Gasoline, Diesel, and other Fuels. These systems are fully optimized by utilizing precision sampling and analysis systems.

These systems leave the Technics facility with the required valves, flow meters and other instruments pre-wired to the integral SCADA system with local operator interfaces. A computer and software package is provided for remote control, monitoring, and reporting.

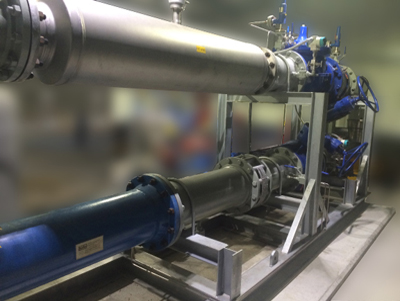

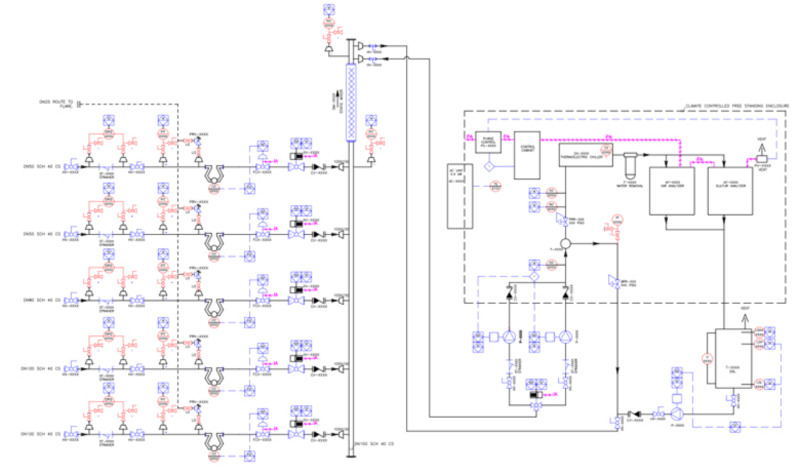

A typical process moves feedstocks through double block and bleed manual ball valves with each stream monitored for pressure. A coriolis meter provides volumetric and mass flow rate levels as well as a direct density measurement while flow control valves throttle the feedstocks proportionally to provide the proper blended product. Prior to injection in the blend header, actuated valves are used to isolate the channels.

The homogenization occurs in the blend header by use of a static mixer (alternatively, a jet mixer is used to avoid pressure loss). In-Tank Mixers are a further alternative.

These systems leave the Technics facility with the required valves, flow meters and other instruments pre-wired to the integral SCADA system with local operator interfaces. A computer and software package is provided for remote control, monitoring, and reporting.

A typical process moves feedstocks through double block and bleed manual ball valves with each stream monitored for pressure. A coriolis meter provides volumetric and mass flow rate levels as well as a direct density measurement while flow control valves throttle the feedstocks proportionally to provide the proper blended product. Prior to injection in the blend header, actuated valves are used to isolate the channels.

The homogenization occurs in the blend header by use of a static mixer (alternatively, a jet mixer is used to avoid pressure loss). In-Tank Mixers are a further alternative.

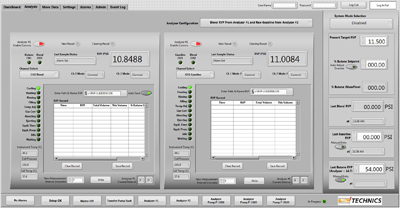

A sampling quill withdraws blended product from the discharge header and transfers in in a fast loop for analysis. Two rotary vane pumps are normally used in a duplex configuration allowing for back up in the event of failure. The transfer pump moves the sample rapidly to the analyzers and return the unused portion back to the discharge header.

Blended Fuel for sampling exits a Swirl filter and is conditioned for pressure, temperature, and water content before entering the analyzers. These analyzer discharge the analyzed fuel into an atmospheric tank which automatically returns the waste fuel to the discharge header.

The key to a high performance Fuel Blending System resides in the analysis for such things as Sulfur, Vapor Pressure, Density, and Octane. Technics can adapt many combinations of analyzers to serve the need of the refinery. See our Online Analysis section for more information

Blended Fuel for sampling exits a Swirl filter and is conditioned for pressure, temperature, and water content before entering the analyzers. These analyzer discharge the analyzed fuel into an atmospheric tank which automatically returns the waste fuel to the discharge header.

The key to a high performance Fuel Blending System resides in the analysis for such things as Sulfur, Vapor Pressure, Density, and Octane. Technics can adapt many combinations of analyzers to serve the need of the refinery. See our Online Analysis section for more information

Just as critical to an effective blender is the control system.

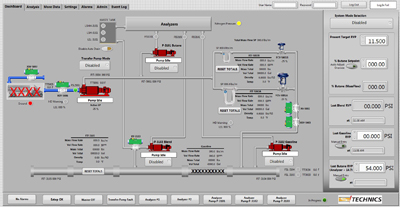

These systems utilize Technics’ LOGOS as the software management and operator interface platform. A local HMI provides access to all of the systems parameters and has a graphical interface to the process. A SCADA system is included with a workstation, monitors and all peripherals.LOGOS provides for precise blending and monitoring of any parameters available to the data acquisition system and the analyzers. The user can select a ratio control mode or an automatic update based on any of the measured variables. This feature adjusts the ratio of the feed streams such that the blend is optimized for Sulfur or Density or Viscosity as measured by the controller.

In addition the LOGOS system typically has the following features

- A graphical representation of the process

- Manual and Automatic Mode

- User Access control for Administrator, Supervisor, and Operator.

- Adjustable alarm levels for all parameters with date and time stamped alarm log.

- An event log to track changes to setpoints

- Full interface to the analyzers through Modbus digital communications eliminate resolution loss.

- A histogram recorder.