lightbox view

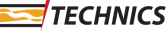

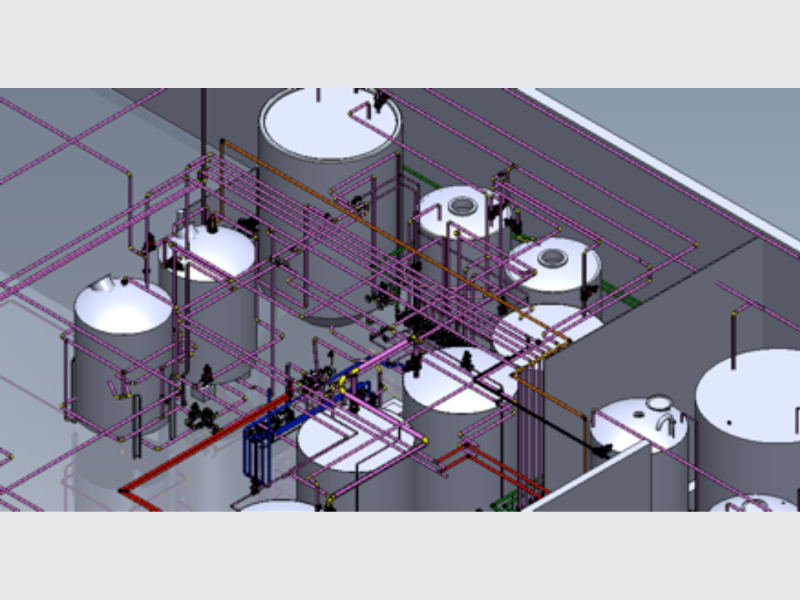

Rosneft (Angarsk, Russia)

Rosneft (Angarsk, Russia)

This project involves a complete design and equipment supply for a 250,000 metric ton blending plant using both batch kettle and inline blending. The equipment includes polymer dissolvers, mixing kettles, directional manifolds, inline blenders, drum decanting units, and pigging systems. The SCADA uses LOGOS software and process automation controllers with thousands of IO.

lightbox view

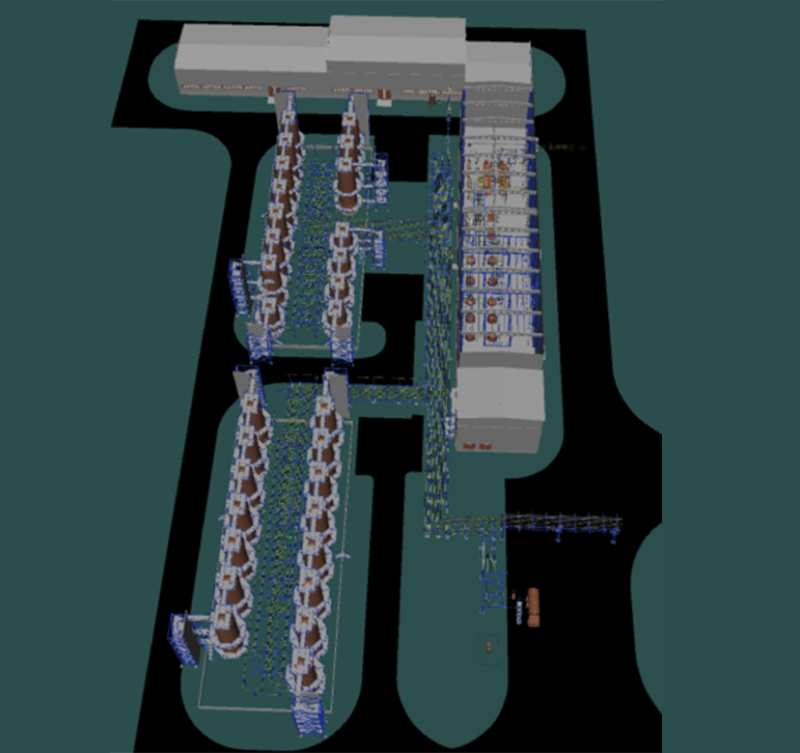

Total Petroleum (San Juan, Puerto Rico)

Total Petroleum (San Juan, Puerto Rico)

Technics supplied an inline blender for this bulk fuel terminal that used LOGOS Blending Software in concert with Allen Bradley’s Compact Logix controller.

lightbox view

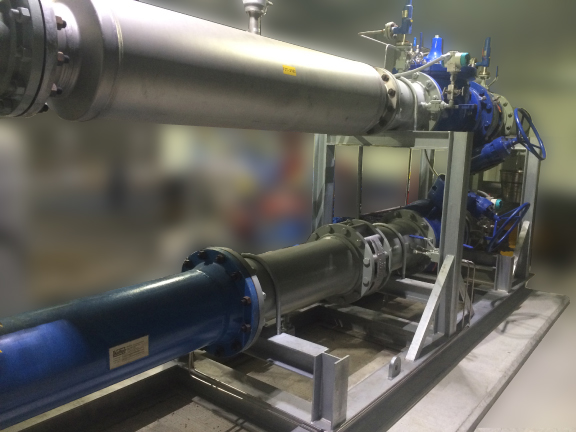

Puma Energy (Managua, Nicaragua)

Puma Energy (Managua, Nicaragua)

Technics designed and supplied an inline blender for this refinery in order to optimize the refining process. Technics LOGOS blend software and National Instruments’ Compact RIO fulfilled the SCADA requirements.

lightbox view

US Oil (Wisconsin, USA)

US Oil (Wisconsin, USA)

Technics designed, fabricated and commissioned butane into gasoline blending systems for three bulk fuel terminals.

lightbox view

Lubrizol (Chicago, USA)

Lubrizol (Chicago, USA)

Technics performed several process and automation upgrades to enhance wax and varnish production including creating a unique inline blending system. The automation was accomplished with Honeywell Experion and several distributed HC900 PLC’s

lightbox view

Oil Libya (Addis Ababa, Ethiopia)

Oilibya (Addis Ababa, Ethiopia):

Technics delivered its LOGOS based ethanol blending skid to the Akakai Fuel Terminal. The system provides precise blending of ethanol in gasoline at flow rates to 2200 LPM.

lightbox view

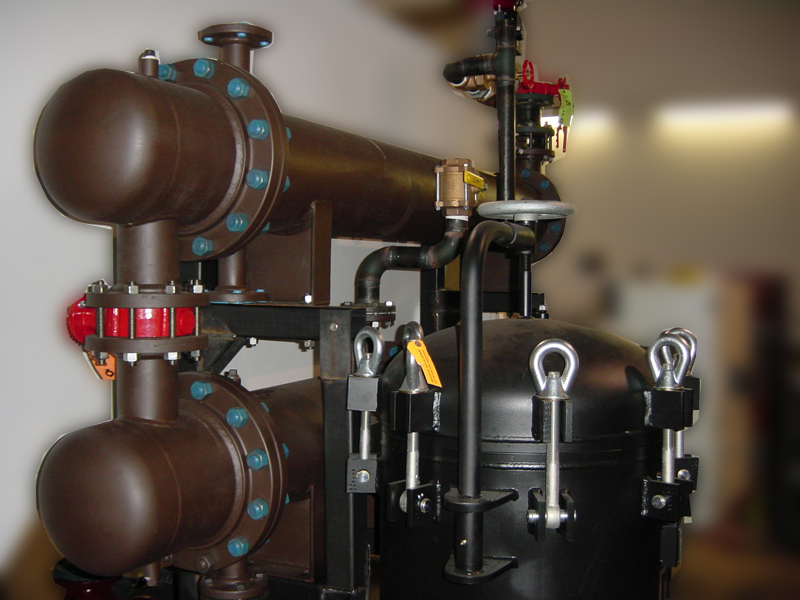

South Refineries Company (Basra, Iraq)

South Refineries Company (Basra, Iraq)

Technics supplied two six channel inline blenders to produce turbine oils. The system includes inline dehydration. The system utilizes Technics’ LOGOS software and a CompactRIO process automation controller.

lightbox view

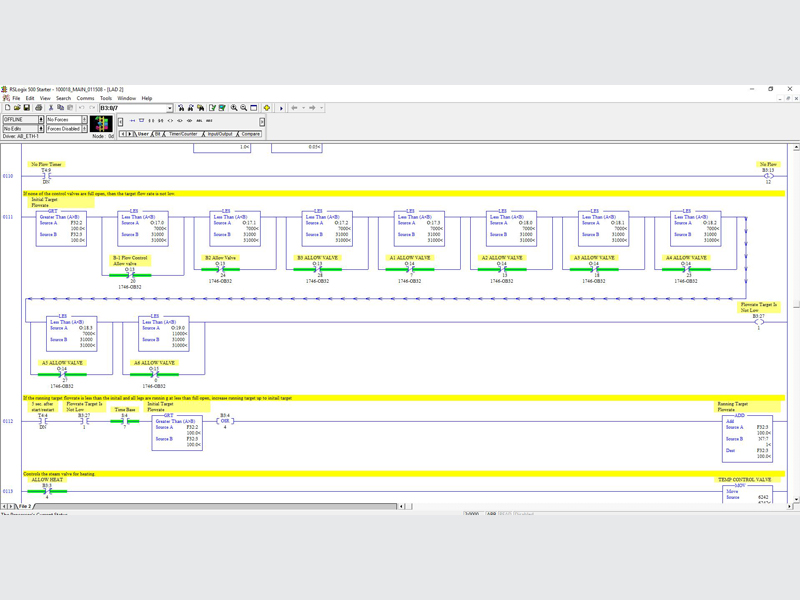

AMSOIL (Wisconsin, USA)

AMSOIL (Wisconsin, USA)

Technics performed System Integration to automate this medium sized lubricant blending plant with its LOGOS Software and Allen Bradley PLC’s.

lightbox view

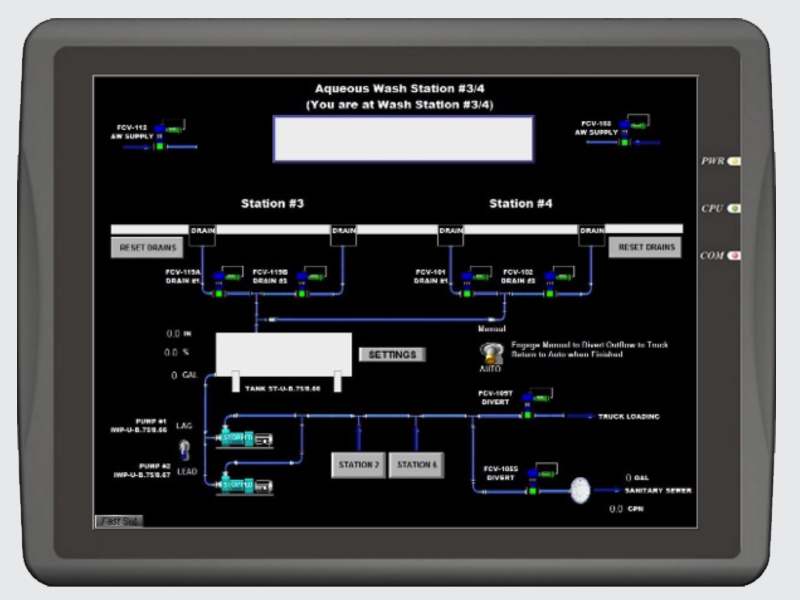

Boeing (South Carolina, USA)

Boeing (South Carolina, USA)

Technics provided the process equipment and automation necessary to manage the washdown waste water generated by the 787 Dreamliner production line. Honeywell HC900 and Maple Systems HMI were used.

lightbox view

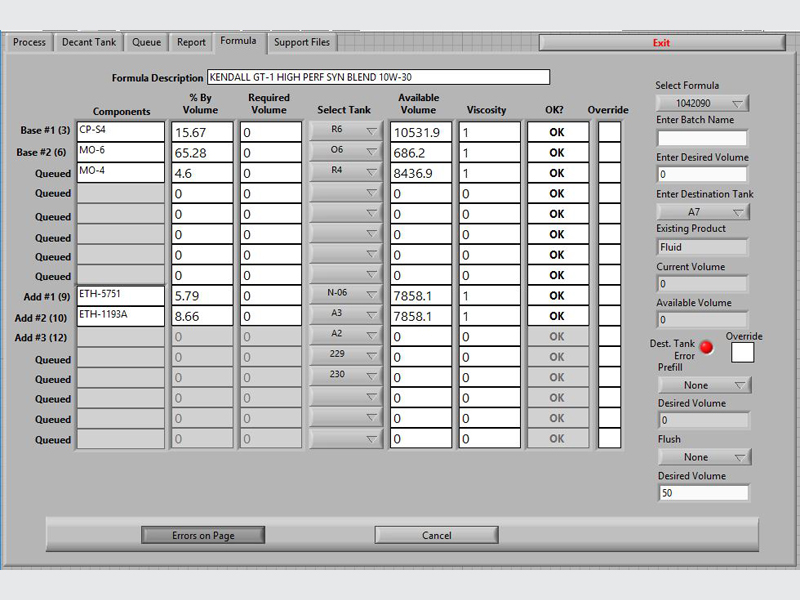

Warren Distribution (West Virginia, USA)

Warren Distribution (West Virginia, USA)

Technics performed System Integration to automate this medium sized lubricant blending plant with its LOGOS Software and Allen Bradley PLC’s.

lightbox view

Advanced Lubrication (Pennsylvania, USA)

Advanced Lubrication (Pennsylvania, USA)

Technics performed System Integration to automate this medium sized lubricant blending plant with its LOGOS Software and Allen Bradley PLC’s.

lightbox view

Tempel Steel (North America)

Tempel Steel (North America)

This manufacturer of stamped components required a high volume storage and transfer system to feed flammable stamping lubricants to a bank of high-speed presses. Technics built several highly reliable fully automatic systems for production level transfers, at facilities in both the USA and Mexico.

lightbox view

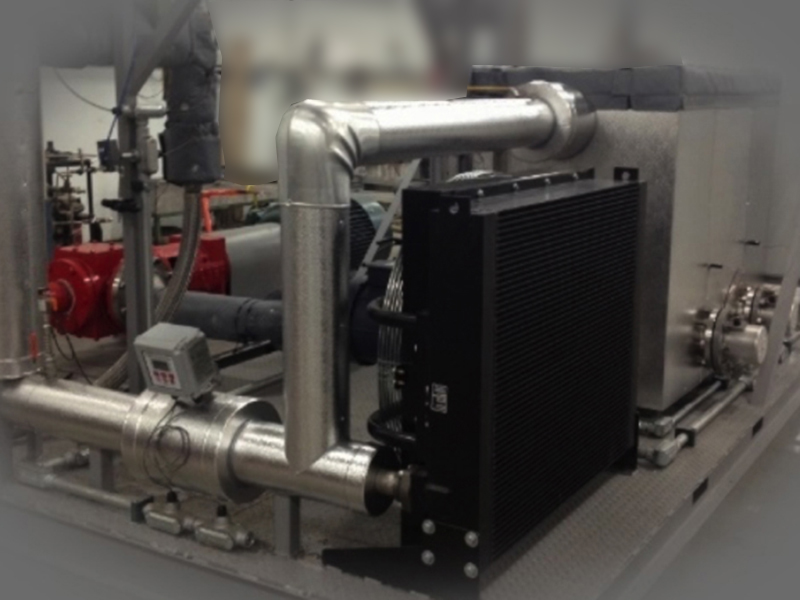

ITW (Ohio, USA)

ITW (Ohio, USA)

Technics designed and supplied a high performance pressure/flow test bench for this manufacturer of automotive thermal management systems. This test rig provided both heating and cooling in a closed loop with National Instruments and Compact RIO providing the SCADA.

lightbox view

Bosch (Aveiro, Portugal)

Bosch (Aveiro, Portugal)

Technics supplied a Pressure Cycling Test Stand for this manufacturer of Tankless Water Heaters. The system is designed to simulator water hammer and does so by imparting a pressure to 30 Bar at 10 Hz. Labview software and Advantech Adam Series fulfilled the DAQ requirement.

lightbox view

BASF (New Jersey, USA)

BASF (New Jersey, USA)

Technics has utilized its the LOGOS engineering and integration system to upgrade an existing Engine Test Cell Fuel Supply System at BASF Catalysts. The system provides bulk storage and transfer of ten separate fuels delivered to over twenty test cells.

lightbox view

Honeywell Aerospace (California, USA)

Honeywell Aerospace (California, USA)

Technics supplied a fully integrated mobile platform for liquid cooling thermal management. The machinery supports development work for hybrid powertrains as part of the Army FCS program. This particular machine includes an integrated refrigeration system providing 10 kW of cooling.

lightbox view

BAE Systems (California, USA)

BAE Systems (California, USA)

Technics supplied a number of mobile liquid cooling thermal management systems to this global defense contractor in further support of the Army’s FCS Hybrid powertrain development program. Cooling systems range form 5 KW for battery packs to 250kW.

lightbox view

Honda R&D Americas (Ohio, USA)

Honda R&D Americas (Ohio, USA)

Technics provided a variety of test equipment for the fuels lab including; Conditioned Refueling, In-Vehicle Fuel Heating, Pressure Vacuum Cycling, and High Accuracy Fill. Labview and National Instruments Hardware was utilized.

lightbox view

TI Automotive (Tian Jin, China)

TI Automotive (Tian Jin, China)

Technics supplied their conditioned refueling cart for this automotive supplier. This process included vapor recovery simulation and uses an Allen Bradley PLC in conjunction with Labview Software.

lightbox view

General Dynamics (Ohio, USA)

General Dynamics (Ohio, USA)

Technics designed and supplied a Coolant Charging Cart for the production line of this military equipment manufacturer.

lightbox view

NASA (Ohio, USA)

NASA (Ohio, USA)

In support of the NASA’s Ares III Crew Launch Vehicle, Technics has designed and furnished an integrated hydraulic charge cart for the upper stage thrust vector control.

lightbox view

Fermi Accelerator Laboratories (Illinois, USA)

Fermi Accelerator Laboratories (Illinois, USA)

Technics designed and fabricated this simple cooling system for the radioactive water heated by their high energy physics equipment.

lightbox view

Modine Manufacturing

Modine Manufacturing:

Technics, Inc. supplied a High Volume Coolant System to support this North American Technical Center of the world’s largest supplier of heat transfer technology to the automotive industries. The skid-mounted unit provides a coolant supply up to 600 GPM to a series of Radiator Test Cells under a varying thermal load.

lightbox view

Senior Automotive (Illinois, USA)

Senior Automotive (Illinois, USA) Senior Technics supplied a four channel pressure fatigue test stand for this manufacturer of EGR coolers. Using National Instruments’ Compact DAQ and Labview, the test stand can perform pressure cycles up to 350 PSI at rates in excess of 20 Hz.

lightbox view

Argonne National Laboratories (Illinois, USA)

Argonne National Laboratories (Illinois, USA)

Technics designed and built a multi-channel gas blender for this national laboratory studying the use of synthetic gasses on both combustion and turbine engines. National Instruments CompactRIO was used in conjunction with Labview Software.

lightbox view

Kautex Textron (Ontario, Canada)

Kautex Textron (Ontario, Canada)

Technics supplied their conditioned refueling cart for this automotive supplier. This process included vapor recovery simulation and uses an Allen Bradley PLC in conjunction with Labview Software.

lightbox view

Roper Pump (Georgia, USA)

Roper Pump (Georgia, USA)

Technics delivered an endurance test stand for high pressure down hole well pumps. The system uses Compact RIO with Labview software to control fluid temperature to 350°F, pressures to 750 PSIG, and power to 125 HP.

lightbox view

Telleborg Vibracoustic (Toluca, Mexico)

Telleborg Vibracoustic (Toluca, Mexico)

Technics upgraded this automotive suppliers Burst Test Stand with computer controlled automation and DAQ capabilities.

lightbox view

Harley Davidson (Pennsylvania, USA)

Harley Davidson (Pennsylvania, USA)

Technics supplied the fuel delivery system for the end-of line roll test at Harley Davidson’s reconfigured motorcycle plant. The system has a dual setting for fuel delivery pressures and is designed to provide the highest level of safety and functionality.

lightbox view

Scientific Applications International (California, USA)

Scientific Applications International (California, USA)

Technics supplied a conditioned fuel consumption measurement system to this defense research consortium. The system utilized Technics’ Baseline Series controller to provide wide ranging fuel selections at various temperatures and pressures while precisely measuring engine consumption.

lightbox view

Invensys Controls (Illinois, USA)

Invensys Controls (Illinois, USA)

Technics, Inc. supplied its Baseline Series controller in valve configuration to Invensys Control Systems. The integrated test stands performs an endurance tests on gas valves at pressures as low as 5 inch WC.

lightbox view

GM Holden (Melbourn, Australia)

GM Holden (Melbourn, Australia)

Technics provided its Conditioned Refueling System to the Holden Subsidiary of General Motors. The system is used for fill-performance tests on all Holden vehicles under development. The system delivers fuel at precise flowrate to 100 LPM and temperatures between -17C up to 40C.

lightbox view

Ford Motor Company (Michigan, USA)

Ford Motor Company (Michigan, USA)

Technics supplied its Universal Filter Test System from Ford Motor Company, the world’s number 2 auto maker. The modular system is capable of performing a multitude of tests on filters and strainers including flow/pressure performance as well as single and multi-pass efficiency testing. The system is capable performing high vacuum to 300-psi tests at flow rates to 10 GPM. In addition to particle counting the temperature controlled system unit can derive air entrainment data.

lightbox view

Kia Korea

Kia Korea:

Our Korean Partners assisted us in providing delivery of several of Technics' computer controlled, fuel conditioning carts used by OEM’s and Tier 1 suppliers for validation of environmental compliance and fill performance testing.

lightbox view

General Motors (North America)

General Motors (North America)

Technics provided specialty mobile refueling systems in Michigan, Colorado, California, and Mexico City providing temperature and flow controlled fuel delivery to vehicles under performance and environmental tests. The computer controlled fuel conditioning units were provided with options to meet the needs of each facility from control only to reporting and analysis software.

lightbox view

Toyota (Alabama, USA)